.jpg)

.jpg)

.jpg)

| Model | Component% | |||

| 60# | SiC | F.C | Fe2O3 | |

| 65# | 60min | 15-20 | 8-12 | 3.5max |

| 70# | 65min | 15-20 | 8-12 | 3.5max |

| 75# | 70min | 15-20 | 8-12 | 3.5max |

| 80# | 75min | 15-20 | 8-12 | 3.5max |

| 85# | 80min | 3-6 | 3.5max | |

| 90# | 85min | 2.5max | 3.5max | |

| 95# | 90min | 1.0max | 1.2max | |

| 97# | 95min | 0.6max | 1.2max | |

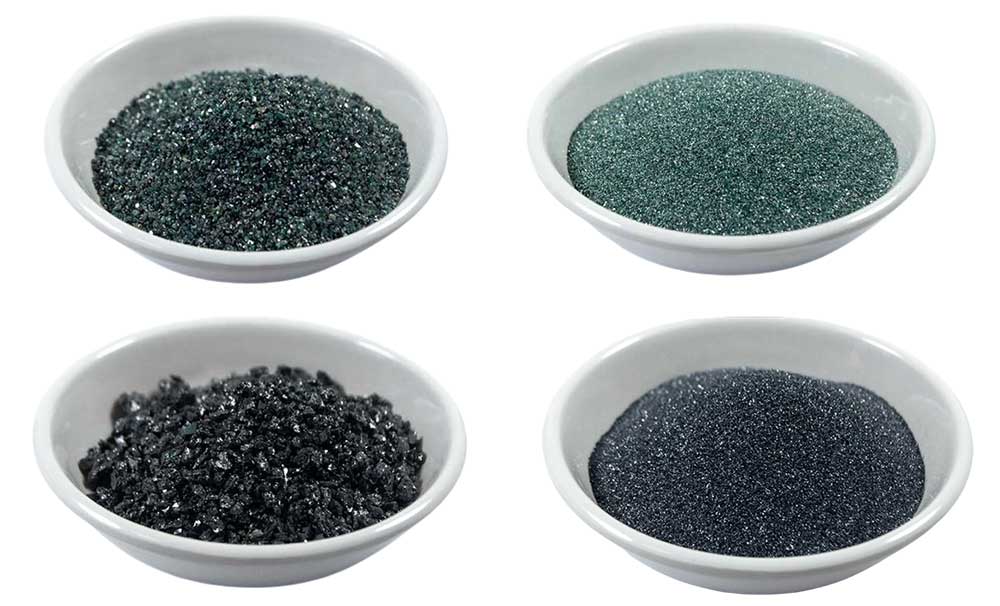

| Green silicon carbide | |||

| Size | SiC > | Free carbon < | Fe2O3 < |

| 12#-90# | 98.5 | 0.2 | 0.6 |

| 20#-90# | 99 | 0.2 | 0.2 |

| 100#-180# | 98 | 0.3 | 0.8 |

| 220#-240# | 97 | 0.3 | 1.2 |

| Grade | Chemical Composition % | ||

| SiC | F.C | Fe2O3 | |

| ≥ | ≤ | ||

| SiC98 | 98 | 0.3 | 0.8 |

| SiC97 | 97 | 0.3 | 1 |

| SiC95 | 95 | 0.4 | 1 |

| SiC90 | 90 | 0.6 | 1.2 |

| SiC88 | 88 | 2.5 | 3.5 |

.jpg)

.jpg)

.jpg)